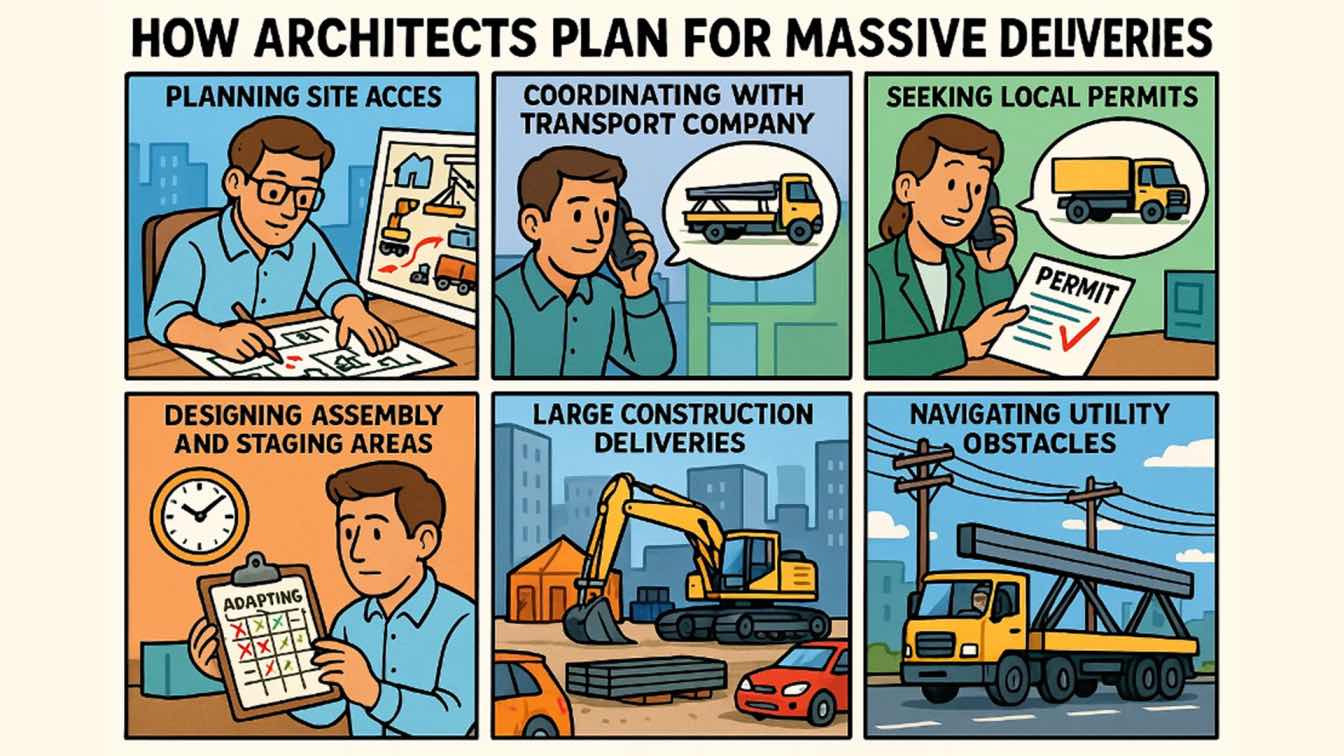

When large construction pieces hit the road, architects need more than blueprints.

Oversized deliveries call for clever planning. They demand solid site prep and smooth teamwork with transport pros. Everyone involved—think city officials, neighbors, crews—wants as little disruption as possible!

Architects start mapping out access points long before delivery trucks arrive. They watch clearances and plan routes down to inches.

Read on for a real look at how those massive beams and prefabs reach your jobsite without a hitch.

Planning Site Access for Large Deliveries

Expecting massive equipment or materials means one thing. The need to ensure adequate space and a clear path from street to site. Architects often review access routes with tape measures and site maps in hand, with tight turns or low-hanging wires that could snag a delivery in mind.

Extra gravel may be spread for support on soft ground. Curbs sometimes get removed weeks ahead of time so trucks don’t get stuck trying to squeeze past narrow corners. Nothing gets left to chance when size matters most.

Coordinating with Transport Companies Early

Knowing what’s on the way shapes everything. Every oversized beam, steel truss, or modular panel comes with its own specs—dimensions, weight, quantity—that must be mapped out early.

Architects talk closely with suppliers and logistics teams to confirm every detail in advance. Sketches get updated as soon as changes pop up. Timelines are built around transport schedules, so nothing arrives before crews are ready.

Let’s say the deliveries are coming from the Great White North. Regular check-ins with the chosen Canada oversize load transport company are paramount. Prompt communication and clear documentation help keep both border requirements and timing in sync for a smooth arrival on site.

Managing Urban Traffic and Street Closures

Picture a modular unit crawling through busy city streets. You can’t just hope traffic clears on its own. Architects meet with city planners and traffic engineers well in advance, mapping out the route and pinpointing where temporary street closures or detours are needed.

Advance notice lets everyone… neighbors, local businesses, commuters… plan around delivery day. Police or flaggers might be stationed along tricky sections to guide trucks safely through crowded intersections while keeping daily routines moving as smoothly as possible.

Designing for Assembly and Staging Areas

Big deliveries rarely go straight into place. Architects often need to carve out extra zones onsite, where large components can be stored or assembled before final installation.

You might see a steel girder resting on timber cribbing, waiting its turn, or crews bolting together wall panels beside the foundation. Different types of heavy construction equipment sometimes call for unique platforms or temporary supports during assembly.

Early site layouts account for these staging needs, preventing crowding and keeping workflow organized while massive pieces get prepped for the build.

Navigating Power Lines and Utility Obstacles

Safety is also quite crucial during the transportation and delivery of massive construction material and equipment. Overhead powerlines pose real hazards when extra-tall loads roll in, as do water mains or gas pipes beneath temporary routes.

Averting risks often requires:

- Raising low wires ahead of time

- Marking buried utilities on detailed maps

- Scheduling utility shutoffs if needed

- Consulting local service providers early

Even one missed hazard can halt a project. Architects cross-check all these factors before delivery day to avoid delays, injuries, or damage once shipments arrive.

Working with Local Authorities on Permits

If something gets builders into legal trouble faster than a flash, that’s code and regulation violations. Delivering or anticipating big components often means dealing with:

- Oversize load notifications,

- Securing special transport permits,

- Road use approvals,

- Or even permission for temporary street closures.

Every step depends on where the project is happening, since requirements shift from city to rural site.

Importantly, these measures are about more than paperwork. They help protect everyone’s safety and keep public roads working smoothly while oversized deliveries make their way to the jobsite.

Adapting Delivery Schedules to Minimize Disruption

Construction sites rarely exist in a vacuum. As hinted already, large deliveries have ripple effects on traffic. They affect neighbors and other trades working nearby.

Architects usually review municipal calendars and chat with local businesses before setting a date for oversized shipments. Nighttime or weekend deliveries can cut down congestion in busy areas. Sometimes arrival windows shrink to just a few hours, so the street clears quickly after unloading.

Adjusting schedules this way takes effort upfront but pays off by keeping everyone’s routines moving as normally as possible during construction.

Bottom-line:

Getting large-scale construction elements onsite calls for more than good intentions. Careful planning keeps projects efficient and neighborhoods running. Every decision about delivery and site access helps avoid setbacks, ensuring investments pay off without needless delays or complications down the road.